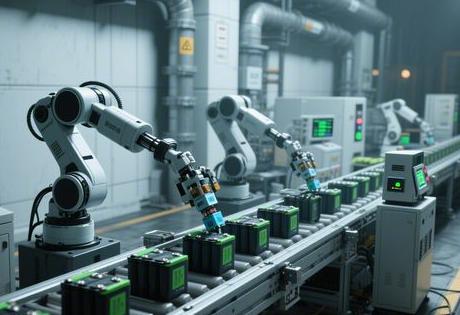

Why other people's battery production line like open hanging, but your always in the "traffic jam"? Conveyor line selection is not right, minutes for you to experience what is called "material in the way". Today, let's break up and talk through--From depalletising to palletising, how newbies can avoid those pitiful selection minefields.

First, first understand: conveyor line is not a belt so simple

You thought conveyor lines were just conveyor belts? You're wrong! There are just three mainstream factions of photovoltaic module lines:

- doubled speed chainChain speed increases the speed of the workpiece board, especially suitable for the assembly of frequent stops and starts. 8 out of 10 lines in Ningde Times workshop use it, why?300kg load, but still stable.The tray is not afraid of falling apart even if it is piled high with cores.

- platenIt can be used to transport large-size modules and heavy Pack boxes with a flat bottom. A China aviation lithium factory used it to transport 25kg aluminium module.Adjust the slope to 3°.The material slides into the station by itself.

- leather belt line: Don't look inconspicuous, it's the king in lightweight scenarios! Like sampling lines, FPC board transport.0.02mm positioning accuracyThe robotic hand is a catch.

Here is a lesson in tears: a factory to save money at the beginning of the ordinary belt line transport module, the results of three months to crush three lines, maintenance costs enough to buy two sets of speed chain ...

Second, depalletising session: robot selection directly determines the efficiency ceiling

The real test begins when the forklift dislikes the mountain of bins to the door of the production line. A newbie's favourite question.Should I choose a robotic arm or a truss machine?

| typology | Applicable Scenarios | Achilles' heel |

|---|---|---|

| Six-axis robotic arm(e.g., Fanuc) | Unstacking of carton/soft pack cores | Shakes to a sieve if the load exceeds 80kg |

| truss robot | Aluminium casing modules/cells | Half a workshop is too much land. |

| collaborative robot | Small batch line with human-machine mixing | Slow as a sloth (<15 boxes/hour) |

A lithium-ion lithium workshop has suffered a loss - using a truss machine to dismantle a tonne bag of graphite powder, resulting in dust filling the guide rails.Monthly shutdown for 48 hours for ash removal. Then I switched to a closed robotic arm + vacuum suction cup for a direct cure.

Third, the invisible killer before palletising: how to jam the yield rate of positioning accuracy

It's hard to get the core to the welding station, but you find it's crooked? The problem often lies in these two links:

- Roller line turner: Centrifugal deflection of the core when cornering? Learn Hinwanta PlusGuide Wheel DampersThe offset is pressed from 5mm to 0.3mm.

- Jacking and lifting mechanism: Big jitter at the moment the top disc is raised? Take a look at the Hive Energy programme -Cylinder + servo motor dual drivePositioning accuracy ±0.02mm

Self-questioning: should sensors be on the high end or not?

If the workshop is very dusty (e.g. liquid injection workshop), don't hesitate to choose theKeens SR-1000 Code ScannerThe dust concentration of 80mg/m³ is still recognised. Ordinary environment with Omron is enough to save enough money to buy three pneumatic marking machine.

Fourth, palletising equipment: saving labour or space? It's a matter of choice.

Palletiser selection is comparable to finding a partner - there is no best, only the most suitable. Focus on three things:

▷ For ultimate efficiency? Choose the truss type

- 4 metres of storage within easy reach

- 12 boxes of batteries in a minute without a breath.

- But! The cost of foundation reinforcement is enough to buy a Wuling Honda.

▷ To be flexible? Choose the robotic arm.

- One day we'll have square shells, the next day we'll have soft packs, and then we'll change the grippers and we'll be done.

- costSlows down to a crawl if the load is over 50kg

▷ Want man-machine collaboration? Choose 3D vision + suction cups

- Like the programme that Wei Chuang did for a factory.Laser scanning + deep learning algorithmsThe shaped Pack box can also be accurately grabbed

- But when the light changes on a cloudy or rainy day, the recognition rate may plummet 30%

V. Tearful experience: these parameters do not see clearly waiting to be pitched

Equipment vendors blowing smoke? Keep an eye on these five parameters to pay less:

- Repeat Positioning Accuracy: <±0.1mm (otherwise the busbar weld will not be aligned)

- Maximum load: 20% discount on the nominal value is the true level (e.g. if 300kg is labelled, use 240kg).

- environmental tolerance: Liquid injection workshop equipment must be IP54 protection, ordinary workshop IP32 enough to use

- failure intervalMTBF > 2000 hours is the bottom line (a factory is greedy to buy the MTBF 800 hours, and repair it five times a month).

- Extended Interface: No Profinet or EtherCAT interface? You'll be crying in three years if you want to connect to an MES system.

And finally, a little bit of offensive truth.

Don't be brainwashed by "full automation"! I visited a factory that spent $8 million on unmanned palletising, but the result was that compatibility was so poor that it took three days of downtime to adjust the equipment for a new type of core. Why don't you learn from some of the production lines of Ningde Times?Leave 1 manual intervention post at key work stations, both to preserve flexibility and control costs. After all, battery technology iterates faster than mobile phones, and the device you buy today may have to be retrofitted by the end of next year. Remember.Conveyor line is not the more expensive the better, is the more "carry made" the more fragrant!