Hey, have you ever wondered why some of those conveyor lines running around in factories can whoosh goods without rollers or chains? Let's break it down today.磁力输送线Contactless drive的三大核心技术The first thing you need to do is to read it and make sure you understand it!

🔍 I. Levitation technology: the magic of making goods "float"

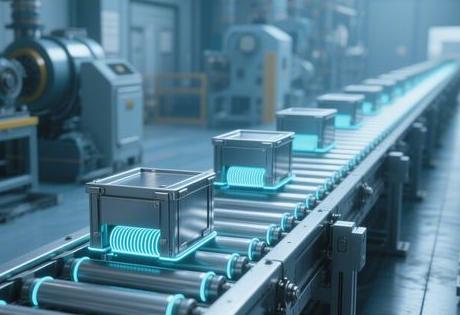

You see, the magnetic drive line holds up the shelves without the use of rollers.magnetic levitation technology. There are two main tricks at work here:

- normal-conducting magnetic suction: It's like two magnets with the same poles repelling each other - the track is energised to create a magnetic field that pushes the carrier up a few millimetres and lets it hang and slide.

give me a chestnut: Auto parts factories no longer have to change chains every month after using this technology, saving a lot of money on repairs. - superconducting magnetic repulsion (SCR): More advanced play! Generate a strong magnetic field with zero resistance superconducting coils that can jack carriers up to tens of centimetres high.

cruxThe suspension is completely frictionless, so that precision instruments can be transported without fear of breaking parts.

⚡ II. Driving Principle: The Invisible "Magnetic Pusher"

Levitation is just the first step, how do you make the shelves move? The answer isMoving magnetic field drive::

- solenoid array: The track is lined with dense coils that take turns energising like a relay race.

effect: The energised coil creates a moving magnetic field, like an invisible hand pushing the carrier forward. - Precise speed control: Adjust the amount of current and frequency of energisation, and the carrier speed can be as fast or as slow as you want it to be.

real-life exampleAfter a mobile phone factory used this technology, the parts conveying speed from 1m/s to 3m/s, the production capacity is directly doubled!

🧠 III. Intelligent control: the "strongest brain" of the conveyor line

It's not enough to move, you have to be smart! It's hidden here.Three Intelligent Systems::

- Real-time monitoring system::

- Hundreds of sensors keep an eye on the carrier's position, temperature, current.

- In case of abnormality, automatically switch the backup line within 0.1 second

- Fault prediction system::

- Relying on big data analysis to predict failures in advance

- for exampleAutomatic speed reduction when coil temperature exceeds the limit

- Collaborative control system::

- Seamless integration with robots and warehouse systems

- Like in a logistics warehouse, when a system command arrives, the magnetic drive line immediately delivers the goods to the robot.

💡 Time for personal opinion

If you ask me, the best thing about the magnetic drive line is not how cool the technology is, it's that itPoking the factory where it hurts::

- Used to be half a day's downtime to change a chain, now magnetic drive line maintenance is reduced 70%

- Precision workshop afraid of dust? Non-contact design makes cleanliness easy to meet the standard.

- The biggest surprise was the scalability! Want to modify your production line? Just add a track like a Lego.

But be warned: superconducting type although levitation high, but have to be equipped with cooling system, small and medium-sized enterprises with normal conduction type is more cost-effective. This technology is now like ten years ago, the electric car - high initial investment, but with three or five years, save the electricity maintenance costs absolutely back to the capital!