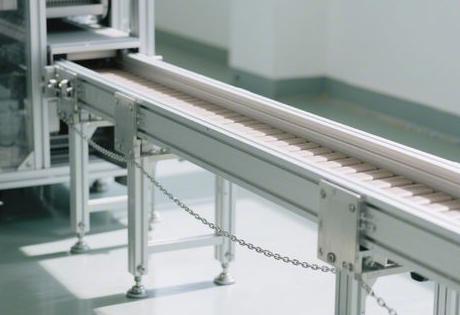

In the sophisticated arena of modern manufacturing, theMiniature Double Speed ChainIt is reshaping the spatial logic of automated assembly lines in a revolutionary manner. This fusion of mechanical dynamics and intelligent control technology not only solves the pain point of the traditional production line's huge space, but also through thevelocity superposition principleA geometric increase in efficiency has been realised. In this article, we take you on an in-depth exploration of this subtle innovation in the field of industrial drives.

I. The core principle of the multiplier chain: a speed revolution driven by structural differences

The essence of a multiplier chain is aComposite Motion Systems--The word "speed" in its name is not imaginary, but originates from its unique physical speed increasing mechanism. When the chain runs at a constant speed, the workpiece-carrying plate can move forward at a speed several times that of the chain, a phenomenon that seems to defy common sense, but in fact is a masterpiece of precision mechanical structure design.

Structural features and movement logic::

- Double Diameter Roller Synergy System: The core of the miniature speed multiplier chain consists of two sets of reducer rollers. The inner small-diameter rollers (diameter d) are in direct contact with the guideway and provide the base conveying power; the outer large-diameter rollers (diameter D) are in contact with the workpiece plate and generate the additional speed by self-rotation.

- velocity superposition equation: Actual speed of the work plate V = chain speed V₁ × (1 + D/d). When the roller diameter reaches 2 times of the roller (D = 2d), the3x speed conveying. This mechanical stepless speed change, realised by means of a diameter difference, becomes the physical cornerstone of efficient conveying.

Materials Science Enabling Miniaturisation: In miniaturised designs, engineering plastics (e.g. POM, nylon composites) are widely used in roller manufacturing. This material not only reduces the overall weight of the chain, but its self-lubricating property also reduces the running resistance of 15%-20%, so that the miniaturised system can still maintain high efficiency under the drive of low-power motors.

II. The subtle architecture of the miniature two-tier system

Conventional single-layer doubling chains often face the waste of return idling in limited space, while the double-layer structure through theVertical space reuseThe solution to this dilemma. The miniaturised design takes this use of space to a new level - a complete circulation system in a space no more than 1.5 metres high.

System Composition Analysis::

- upper working levelThe chain is a 2.5-3 times faster chain and the height is usually designed in the ergonomic range of 750-900mm. Precision guides with a thickness of only 8-12 mm can carry loads of up to 200 kg/m².

- Lower Return ChannelUnloaded pallets return to the starting point at base speed (typically 0.8-1.2m/min) through the lower tier, consuming only 30% of the working tier.

- Vertical Articulation Hubs: The jacking transplanting mechanism is the core component of the bi-level system and contains:

- Servomotor-driven timing belt lifting system

- Guided slides with millimetre positioning accuracy

- Pneumatic-mechanical composite pendulum stopping device

personal experience: The most challenging aspect of miniaturised design is not size reduction, but how to address thermal expansion effects in a limited space. Our nanoscale flexible spacers at the rail joints allow the system to maintain ±0.1mm positioning accuracy under -10°C to 60°C operating conditions - an order of magnitude improvement over conventional structures.

Third, the performance advantage: small space in the big action

The space efficiency revolutionIn the case of electronics assembly, the miniature double-layer system requires only 60% of planar space of a conventional single-layer wire body, but increases the capacity density by 2,20% through vertical circulation.Space utilisation enhancement 40%-60%, which means a lot to the modern factory of inches and inches.

Power performance breakthrough::

- Start-stop response time reduced to 0.3 seconds (1.5 seconds for conventional structures)

- No-load backhaul energy consumption reduced by 70%

- Accelerated wear problems are alleviated and chain life is extended by 3 times.

Precision Control Evolution: Precision parking through three technological innovations:

- Electromagnetic cushion-type stopper, eliminating workpiece impact rebound

- Laser distance feedback system, real-time calibration of stop position

- Optimised roller material, static friction coefficient stable at 0.08±0.01

These techniques allow the workpiece to be in continuous operation and still achieve a±0.1 mm positioning accuracy, providing the possibility for precise robot pickup.

IV. Innovative breakthroughs: the technology behind miniaturisation

Innovative combinations of materials: In the development of the miniature doubling chain, we have creatively used theCarbon fibre reinforced nylon matrix compositesThe material is used to make rollers. This material is 40% lighter than conventional engineering plastics, while its wear resistance index is 85% higher than that of steel, successfully resolving the conflict between "light weight and high strength".

Structural topology optimisation: Reconstruction of chain link design by finite element analysis:

- Skeletonised Chainplates Reduce Weight 30% Maintain Strength

- The roller bearing adopts double-row miniature needle roller structure, radial load enhancement 50%.

- Diamond-like coating on the surface of the pin reduces the coefficient of friction to 0.01.

Drive control upgrade: Replacement of conventional centralised drive with distributed hub motor drive:

- Built-in miniature brushless motor for each link

- CAN bus communication for speed synchronisation

- Energy consumption reduced by 45%, noise control below 55dB

personal viewpoint: This distributed drive architecture could become the standard for future intelligent conveyor systems. In our tests, we found that it not only eliminates chain tensioning deviations, but also makes it possible for a single point of failure not to affect the overall operation - thus increasing system reliability to 99.981 TP3T.

V. Application Scenarios and Maintenance Strategies

Precision Fit Field::

- Consumer Electronics: Mobile Phone Motherboard Inspection Line

- Medical Devices: Minimally Invasive Surgical Instrument Assembly

- Automotive Electronics: ECU Control Module Burn-in

- Precision instrumentation: sensor calibration workstations

Intelligent Maintenance System: In the miniature double-layer multiplier chain, we implant the IoT maintenance ecosystem:

- Vibration sensors monitor link wear in real time

- Automatic lubrication replenishment according to mileage

- Critical component life prediction accuracy of 95%

- Maintenance costs reduced by 60%, unplanned downtime reduced by 85%

Operational contraindications::

- Avoiding start-up in ultra-low temperatures (<-10°C)

- Prohibition of the use of organic solvents for cleaning engineering plastic parts

- Workpiece loads to be controlled in the centre area (eccentricity <5cm)

VI. Future Trends: Vascular Networks for Smart Factories

As Industry 4.0 progresses further, the miniature multiplier chain is evolving from a mechanical conveyor system to aIntelligent Logistics Carrier. We are experimenting with integrating RFID readers into the chain links so that each work plate becomes a data node. Even more promising is theModular self-organising systemsdevelopment - with standard interface modules, production lines can be reorganised within 24 hours to meet flexible manufacturing requirements.

Driven by miniaturisation and intelligence, the new generation of Speed Chain will break through the physical limitations and deeply integrate with digital twin technology. In the future factory, these "thinking chains" will not only be able to carry materials, but also analyse product quality and optimize process parameters in real time, and eventually become the neural network of the intelligent manufacturing system.

Core Q&A on miniature double-deck speed chains

Q1: Does the miniaturised design sacrifice carrying capacity?

A1: Quite the opposite. Through carbon fibre composites and topology-optimised structures, our miniature system reduces its size while inversely increasing its load capacity per unit cross-section by 40% compared to conventional designs, reaching a linear load density of 200 kg/m.

Q2: How to solve the vertical articulation bottleneck of the two-tier system?

A2: Innovative use of three-stage acceleration jacking: the first pre-acceleration to 1.2 times the speed of the workpiece plate into the transplantation machine; lifting process to maintain a uniform speed; to reach the target layer of the second acceleration to match the speed of the upper layer. This "soft landing" technology improves the transfer efficiency by 50%.

Q3: Why are miniature systems better suited for precision manufacturing?

A3: The essence of its strength lies indynamic stabilityThe rotational inertia of the small roller system is reduced to 70%, so that the starting and stopping process will not trigger material displacement; with the air spring damping mechanism, the vibration amplitude is controlled at ±5μm - which is equivalent to 1/20 of a hairline.