Catering reconfiguration with multiplier chain technology

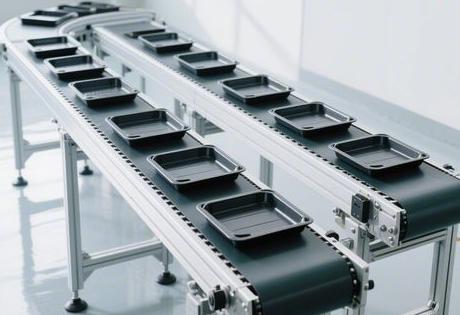

The core breakthrough of the rotisserie multiplier chain is theDeep adaptation of industrial drive technology to catering scenarios. The conveyor belt speed V = motor base speed ν x (1 + D/d) is realised by the difference in diameters between the rollers (diameter D) and the rollers (diameter d) (D/d ≈ 2.5-3.0), and the conveyor belt speed can be up to 2.5 times the chain speed in a typical design. The special requirements of its catering scenario are reflected in:

- Food-grade materials304 stainless steel crescent-shaped chain plate (thickness 1.8mm) with anti-oil and anti-acid treatment to meet the food safety standards.

- silent operationSealed drive system + nylon anti-friction gasket, noise control below 40dB.

- Speed FlexInverter-controlled line speed (2-8 metres/minute) to adapt to different peaks and valleys in passenger flow.

personal experience: During a visit to an online hotpot restaurant in Chengdu, it was discovered that traditional conveyor belts were being used due to theCrescent slice tiltresulting in cutlery slippage rates of up to 3 per cent, while the use ofGroove-flange occlusion structureThe innovative chain (Patent No. ZL202421009613) improves stability by 90% through the interlocking of neighbouring chain pieces - proving that mechanical precision directly determines the customer experience and the rate of ingredient loss.

Innovative design of space and movement

Rotisserie's Speed Chain system reinvents catering efficiency through triple space optimisation:

#####Stereo space compression techniques

- U-shape/loop layout: vertical stacking of preparation area, conveyor belt, and dining seats, with a reduced footprint of 40% compared to a linear layout.

- Double-layer chain belt design: the upper layer conveys the ingredients and the lower layer circulates the empty plates, increasing the space utilisation rate by 300%

- Countertop integrated induction hob: eliminating the separate dining table and embedding the heating module directly in the countertop

#####Dynamic passenger flow response mechanism

| take | Traditional programmes | Speed Chain Solutions | Benefits Enhancement |

|---|---|---|---|

| lunchtime rush | Waiters running to deliver food | Direct conveyor belt access + self-service access | Reduction in service manpower 60% |

| low-flow period | Air conditioning with area-wide lighting | Zone sensing start/stop | Reduced energy consumption 35% |

| Food replenishment | Manually patrolling the field to replenish vegetables | RFID Intelligent Detection Residual | Foodstuffs wastage rate reduced by 18% |

#####Human factors engineering optimisation

- Crescent plate width 140mm: optimal sight range for adult pick-ups

- Turning radius ≥50cm: to avoid the centrifugal force causing the soup base to spill.

- Warm yellow light + greenery landscape table: appetite-enhancing visual guide

Technology Convergence for New Industry Trends

The rotisserie hotpot multiplier chain in 2025 presents three major directions of innovation:

Intelligent Service System

- Conveyor belt with embedded load cell: automatic calculation of charge per disc (accuracy ±5g)

- Induction cooker linkage positioning chip: automatic power-off when diners leave their seats

- AR menu projection: real-time display of dish ingredients and calories above the chain plate

Multi-scenario reuse architecture

- Modular chainplates: fill hotpot containers in winter, change sushi trays in summer

- Expandable rail: support 6-30 dining seats flexible expansion

- A shop in Chengdu achieved a hotpot/sushi mode switching time of less than 15 minutes.

Green energy-saving breakthroughs

- Regenerative braking technology: recovery of conveyor belt braking energy (conversion rate 12%)

- Inverter induction cooker with thermal efficiency up to 90%, energy saving 40% than gas cooker

- Chongqing Pilot Store Comprehensive Energy Consumption Reduced to 0.8kWh/customer

Cost Modelling and O&M Strategy

Although the initial investment in the Peppy Chain equipment is higher than that of a traditional hotpot restaurant by 30% (about 150,000-250,000 RMB), itsimplicit economic valueRemarkable:

- labour cost: Reduction of service staff from 12 to 4, annual labour savings ¥540,000

- Food control: Intelligent replenishment system reduced wastage rate from 8% to 3.5%

- ping yi revolution: Revenue per unit area ¥12,600/m2/year (conventional shop ¥5,800)

case in point: Suzhou's "Shabu Shabu Times" hotpot restaurant after remodelling:

- Turnover rate: 2.5 rounds at lunchtime → 4.1 rounds

- Unit price: ¥68 → ¥82 (premium from experience upgrade)

- ROI cycle: 14 months

Self-questioning: core industry concerns

Q1:How to solve the problem of soup spilling and chain plate cleaning?

Triple Protection System::

- Centrifugal force compensation guide: Turning section speed reduction 30% + tilt angle compensation design

- Food-grade silicone bowl mat: increase friction of container

- Removable chain plate structure: support high-pressure water gun rinsing

Q2: What scenarios are most suitable for the Peppy Chain system?

Three types of golden scenarios::

- Shopping mall catering floor (space cost >¥5000/㎡/year)

- Fast food in tourist areas (passenger flow fluctuation >50%)

- Community boutique (unit price >¥80)

Q3: How are maintenance costs controlled?

Predictive maintenance programme::

- Monthly chain lubrication: use food grade lithium grease (dosage saving 40%)

- Reduction gearbox annual inspection: 460# worm gear oil change

- Orbital Nisshin: Magnetic debris collector

Q4: Future direction of technology evolution?

A New Paradigm of Human-Machine Inclusion::

- Robotic arm replenishment system (response time <3 seconds)

- Blockchain ingredient traceability (from farm to chain plate)

- Digital twin preview: simulation of 200% overload conditions

While traditional catering is still struggling between manpower and efficiency, a shop in Hangzhou used the22 metre ring doubler chainBehind the creation of the industry record of receiving 1,420 people in a single day - generating ¥1,800 revenue per hour per metre of conveyor belt - is the resonance of mechanical precision and human catering intelligence. This symbiotic philosophy of steel and food may be defining the next decade of catering industrialisation.